Make Better Decisions Earlier With Aura Particle Analyzers

With the ability to conduct particle analysis in as little as 5 µL, you can get information on particle presence and formation early in discovery and development for critical insight into developability, stability, formulation, manufacturability and more.

Choose the Aura that Works Best for You

How the Aura Family

of Particle Analyzers Work

See More,

Learn More,

Do More—With Less

Combining two powerful technologies into a single innovation, the Aura family of instruments expands what you can accomplish when you can conduct particle analysis at high throughput with low sample volumes.

This state-of-the-art measurement instrumentation integrates advanced image analysis capabilities, enabling precise characterization and quantification of particles, enhancing the reliability and efficiency of your experiments.

See it all

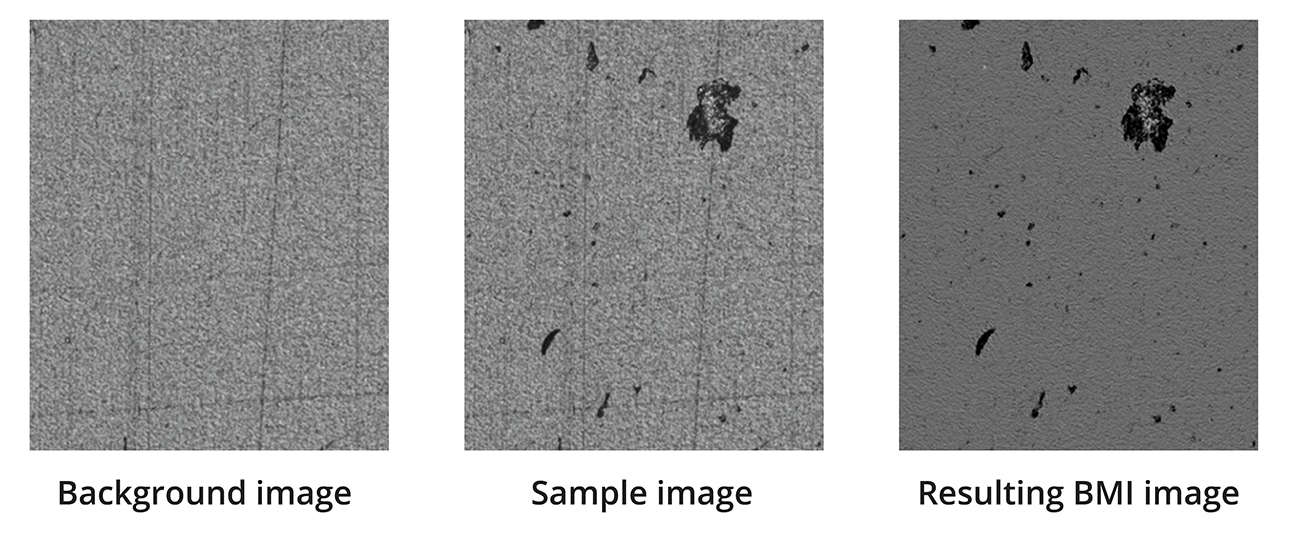

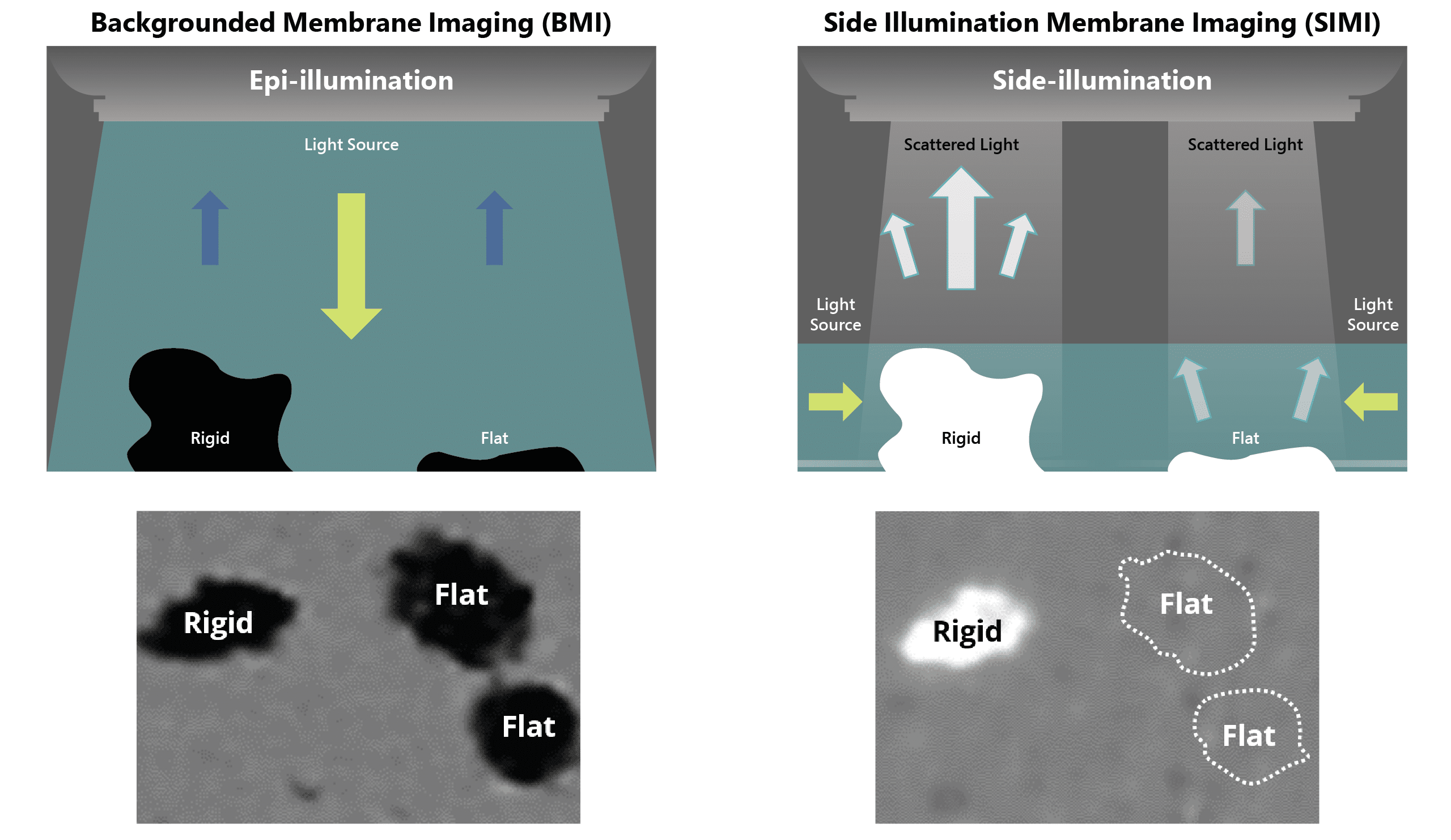

With Backgrounded Membrane Imaging (BMI), Aura instruments give you visibility into every particle in your sample, no statistical adjustments needed.

Identify it all

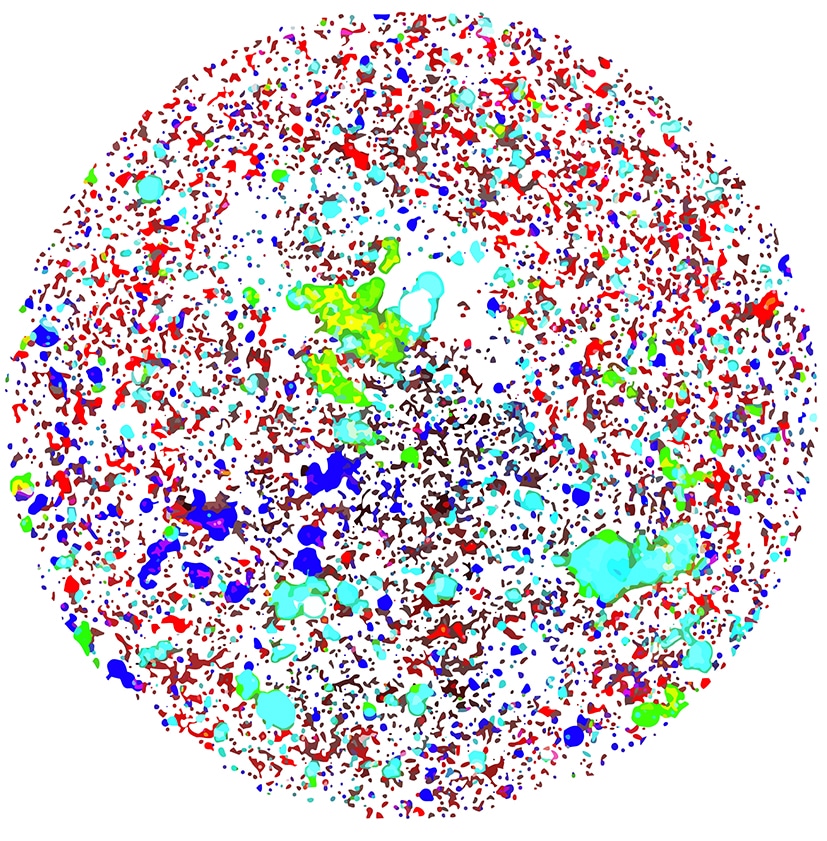

With Fluorescence Membrane Microscopy (FMM), Aura instruments enable identification—not just counting and size—of the particles in your sample.

Do it all

Because Aura instruments work on as little as 5 µL, you can analyze particles earlier in development when you’re working with limited volumes, identifying potential liabilities when it’s easier to re-prioritize.

Aura instruments are also able to support later development activities as they are compliant with USP 788 compendial particle measurements.

Particle Vue Software

Get particle analysis answers in just a few clicks with flexible, easy-to-use Particle Vue Software.

Frequently Asked Questions

A particle size analyzer measures the size distribution of particles in a sample. There are various techniques used in particle size analysis, but one common method is laser diffraction. With this technique, a laser beam is directed through a sample containing suspended particles. As the laser beam interacts with the particles, it scatters in different directions depending on the size of the particles. A detector measures the intensity of scattered light at different angles, and sophisticated algorithms are used to analyze this data and calculate the particle size distribution. Another technique is dynamic light scattering (DLS), which measures the fluctuations in scattered light caused by Brownian motion of particles in solution. By analyzing these fluctuations, DLS can determine the size of particles in the sample. Other methods include sedimentation, microscopy, and electrical sensing. Particle size analyzers provide valuable information about the size distribution of particles in a sample, which is essential in various industries such as pharmaceuticals, cosmetics, and food processing for quality control and product development.

For more information on the different types of particle size analyzers and its importance to ensuring drug safety, check out our blog post.

The most efficient method often depends on specific characteristics of the sample and the requirements of the analysis. However, laser diffraction is widely considered one of the most efficient techniques for particle size analysis. Laser diffraction offers advantages such as rapid analysis times, wide measurement ranges, and suitability for a variety of sample types including powders, suspensions, and emulsions. It provides accurate and reliable results with minimal sample preparation. The Aura family of particle analyzers are quickly becoming recognized for their abilities to generate size, count and aggregate data for fast and accurate particle analysis.

Particle size analyzers provide essential information about the size distribution of particles in a sample. This data is vital for quality control, ensuring product consistency, and meeting regulatory requirements. Particle size analysis is integral to product development, helping optimize formulations and processes. By understanding particle size distribution, manufacturers can enhance product performance, stability, and effectiveness. In addition to measuring particle size, these analyzers are also capable of determining particle concentration, providing a comprehensive understanding of the particle characteristics within a given sample.

Determining the best particle analyzer depends on specific application requirements, such as sample type, size range, and analysis objectives. There isn't a one-size-fits-all solution. However, popular particle analyzers often utilize laser diffraction, dynamic light scattering (DLS), or microscopy-based techniques. The Aura suite of analyzers from Halo Labs can provide more detailed particle analysis than DLS or microscopy for particles ≥1 µm, offering BMI and FMM to find and characterize more particles, including subvisible particles that otherwise go undetected.

Quality control (QC) equipment used for particle size analysis typically includes particle size analyzers such as laser diffraction instruments, dynamic light scattering (DLS) systems, light obscuration, or microscopy-based imaging systems. These instruments allow manufacturers to perform routine analysis of their products to ensure that particle size specifications are met and maintain consistent product quality.