Light Obscuration Is Not Enough to Detect Subvisible Particles

It's no secret that subvisible particulates in biopharmaceutical injections and parenteral infusions can have serious consequences for patient safety.

To mitigate risk, the FDA has mandated stringent quality control regulations regarding lot release and particle size restrictions.

USP 788 outlines two particle detection methods: light obscuration (LO) and membrane microscopy. Despite LO being an accepted technique, relying on it alone is not enough because it fails to provide an accurate count of process impurities in higher viscosity formulations, and it often fails to accurately count protein aggregates.

Luckily, we have just the solution with Aura.

Why Use Aura for Lot Release Testing & QC?

- Meets USP 788 and USP 1788 recommendations – automation-ready, simple and robust workflow, and able to handle complex, high-viscosity, and low-volume samples

- Sample volumes that meet your requirements – accurate analysis with 5 µL – 10 mL of sample

- Achieve higher throughput for testing multiple final product lots in a single experiment

- Gather comprehensive data and insight into aggregate particles – size, morphology, counts, distribution

- Rapid analysis time of about 1 minute per sample

- Benefit from a wide working range: measures particles from 1 μm to 5 mm with high reproducibility

- Differentiate different types of particles

- CFR Part 11 software available

Achieve USP 788 Compliant Analysis with Aura PTx

Aura PTx utilizes Backgrounded Membrane Imaging (BMI) to generate accurate USP 788-compliant subvisible particle (SVP) data, replacing LO so that all particles of interest are covered during lot release testing.

Thanks to its innovative, membrane microscopy-based technology, lot release testing can now be carried out faster, safer, and more reliably, helping identify protein aggregates and process impurities that could otherwise threaten the success of your therapeutic.

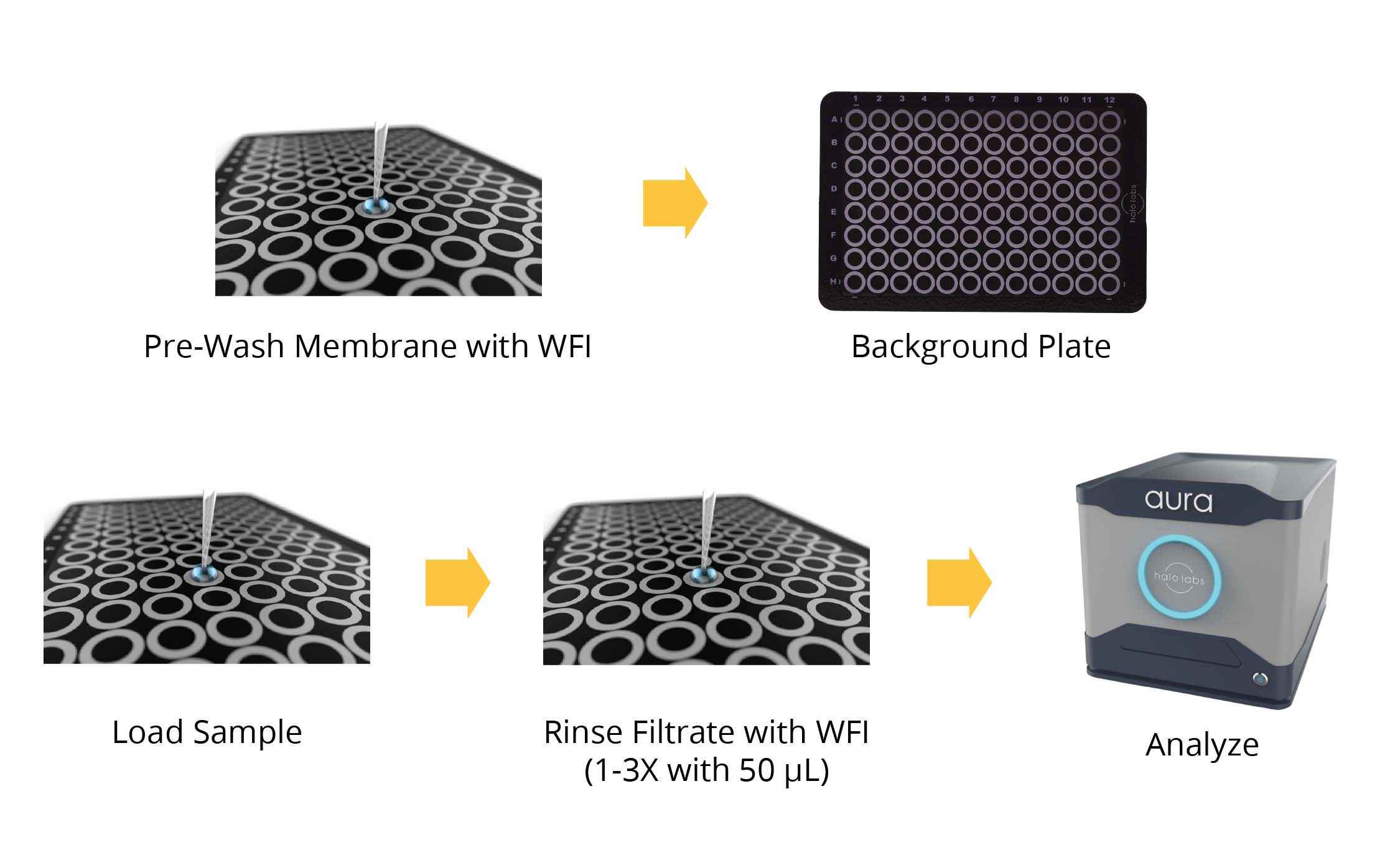

USP 788 Method 2 Compliant Protocol

Following the FDA's USP 788 Method 2 guidelines, we’ve developed an efficient and accurate particle counting protocol for lot release testing using Aura.

With our high-throughput method, pre-washing, backgrounding the membrane, filtering the sample, and washing the membrane again after filtration are required steps to successfully execute an assay in a fraction of the time compared to traditional methods. Efficiency is further heightened when combined with robotic handlers due to our plate's compatibility with robots to give you even faster results.

Experience a Simpler Workflow

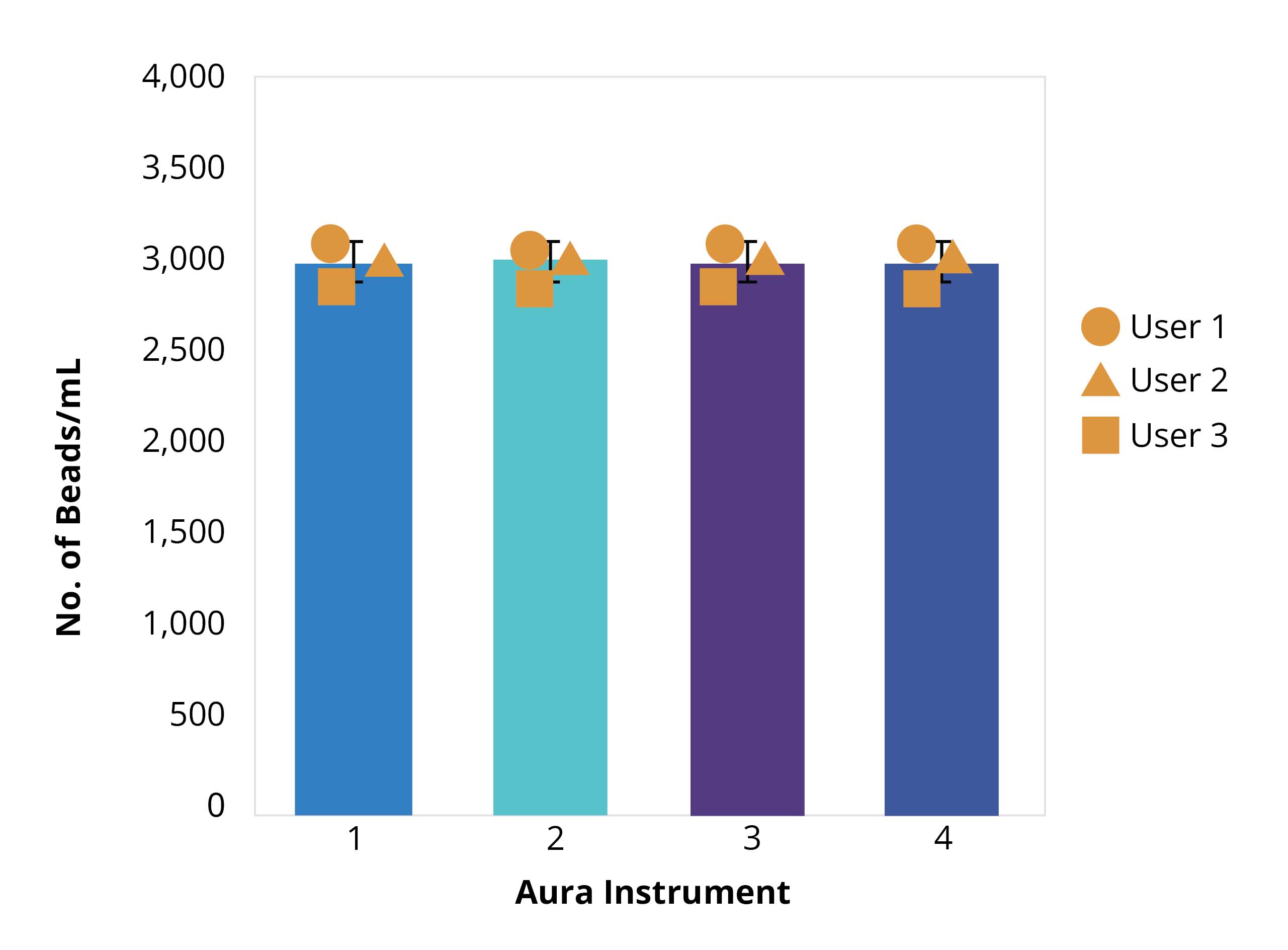

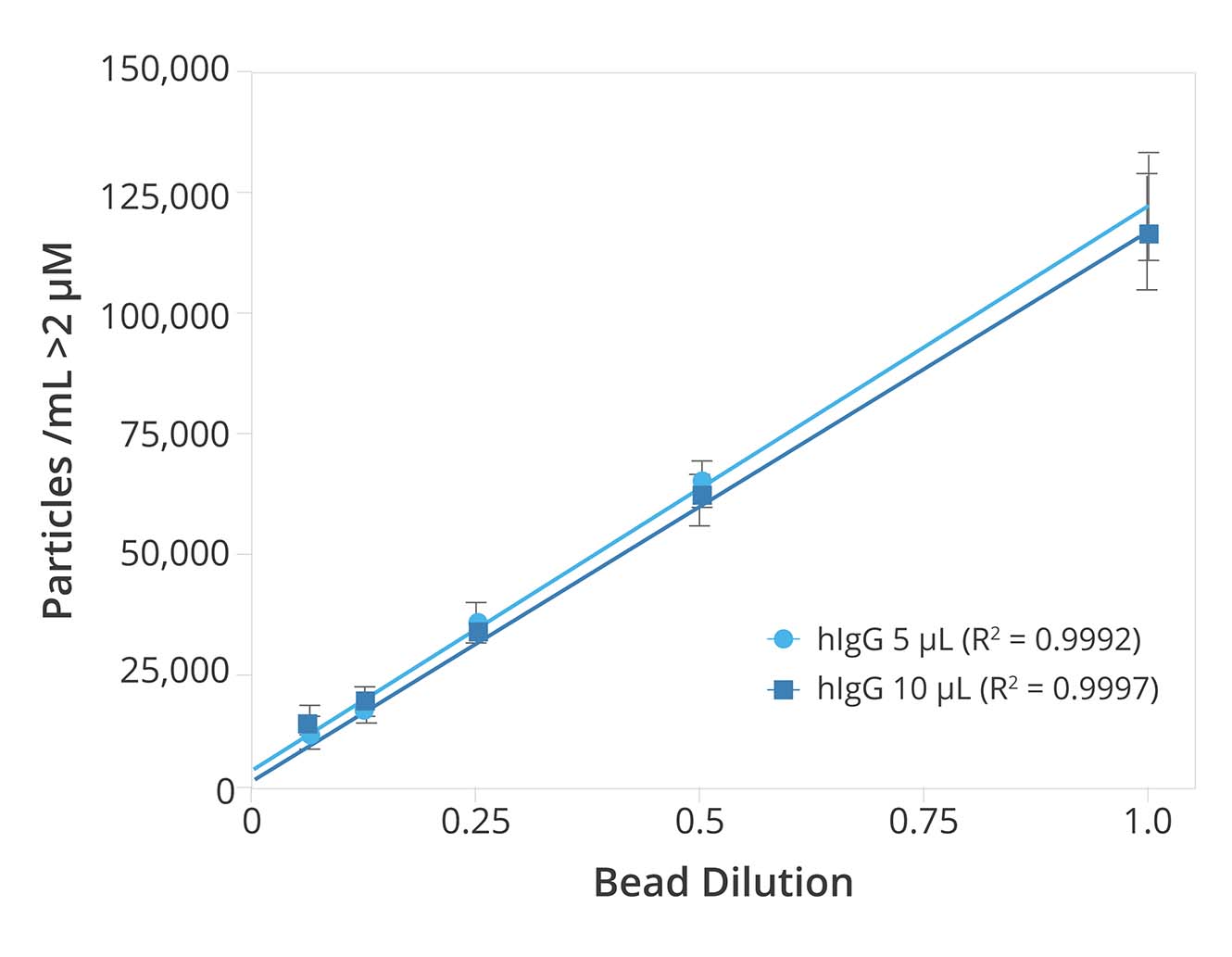

Consistent, reliable results were achieved with four instruments and three users in a study assessing inter-instrument and user reproducibility.

Results of the bead standard analysis showed accuracy within 10%, proving that particle measurements during final lot release testing will be consistent regardless of the instrument or user conducting the analysis.

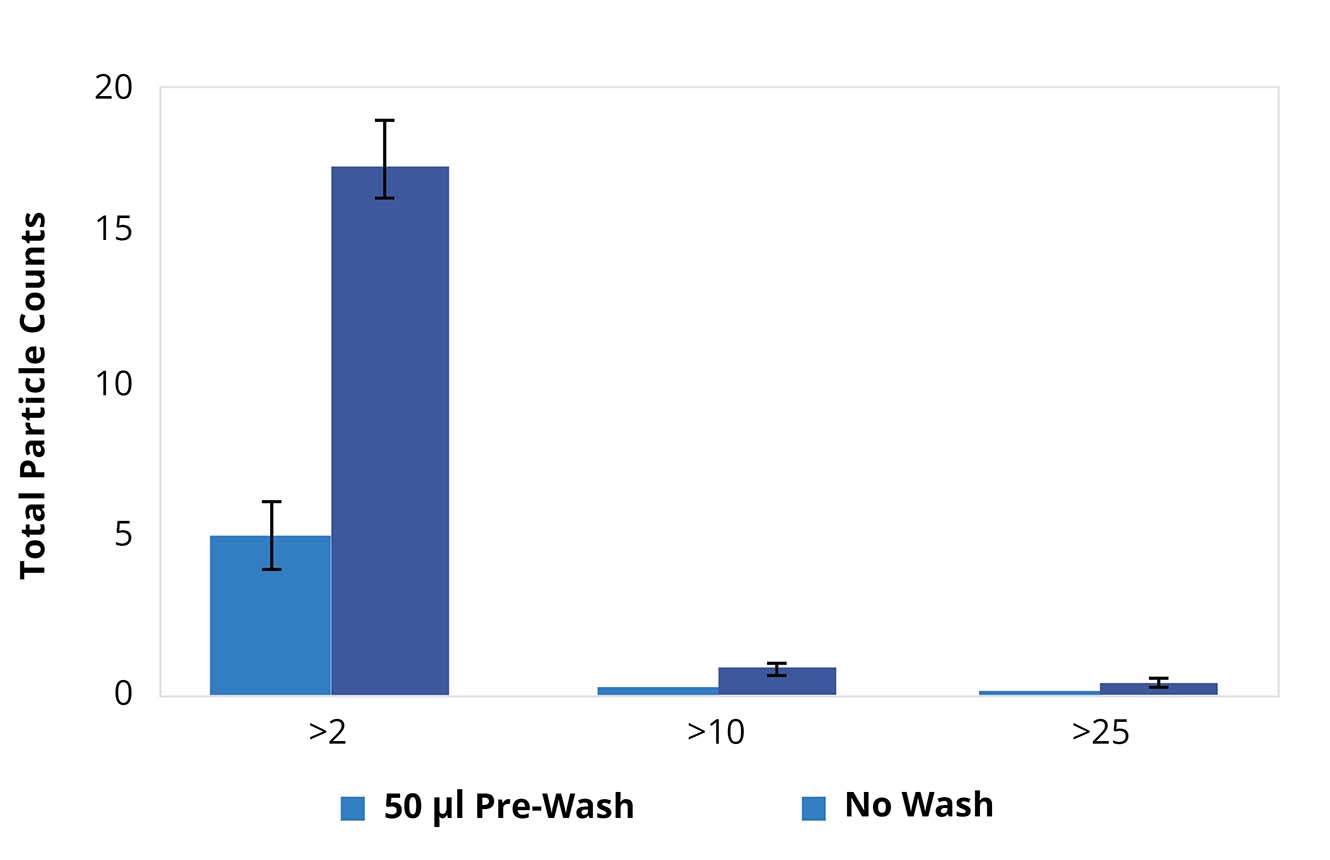

Improve Accuracy with Multiple Membrane Washes

The procedures for washing membranes recommended by USP 788 have a big benefit: they increase the reliability of particle counts.

After the sample has been applied to the membrane, any soluble material, such as proteins and salt crystals, that may cloud the results is washed away with ultra-pure water.

And because Aura PTx can perform multiple measurements, all assay measurements can be more easily validated, adding another level of confidence in their accuracy.

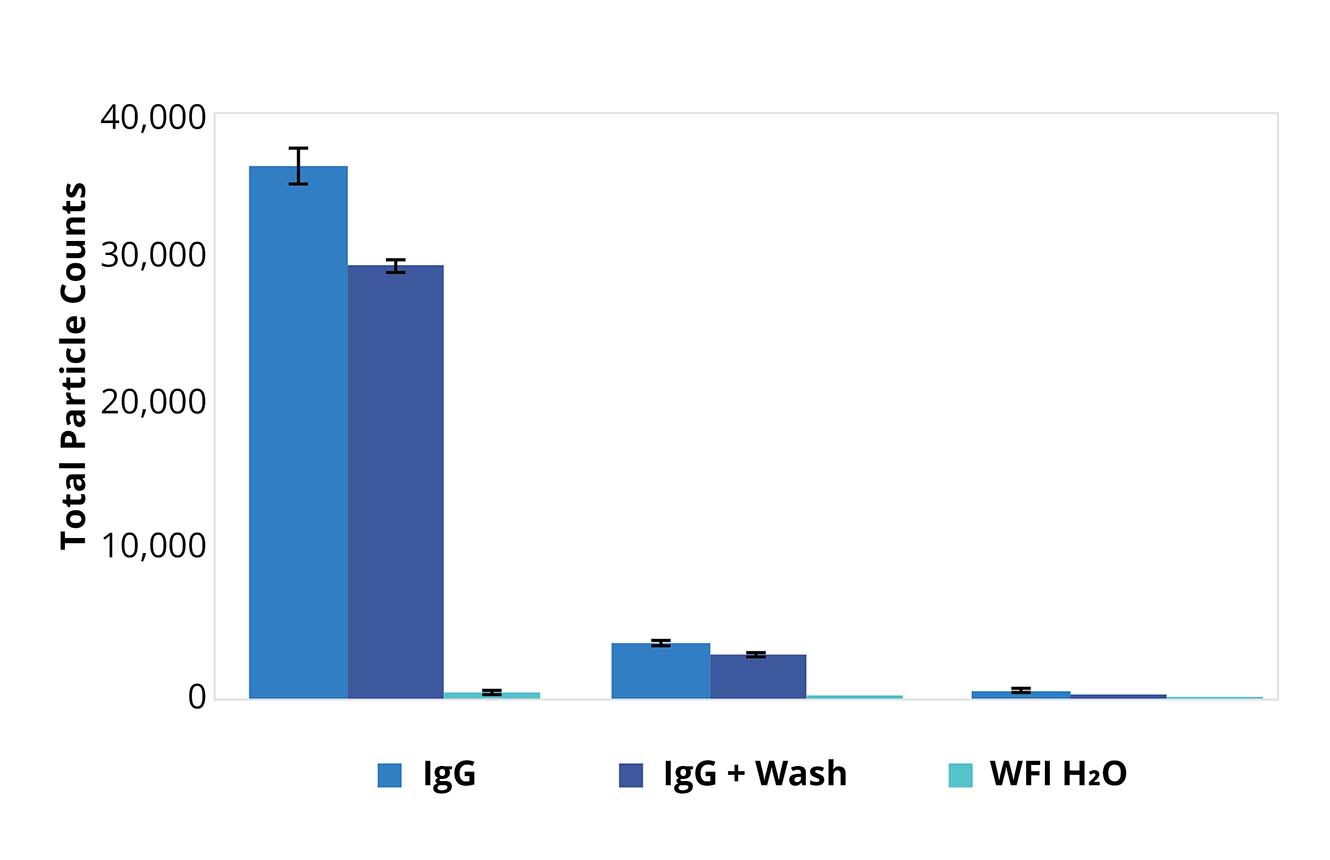

Detect Extrinsics in Highly Concentrated Antibody Formulations

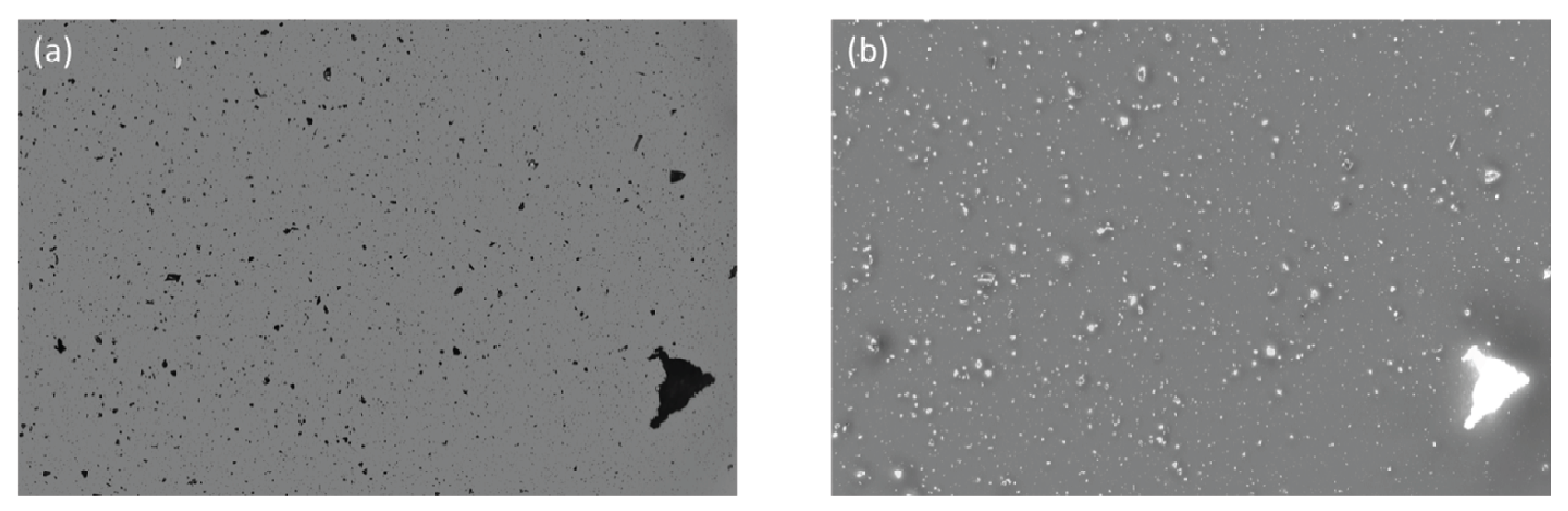

As one of the most harmful intrinsic, extrinsic, and inherent particle types present in commercial antibody formulations, delaminated glass particles can be quickly identified with Aura's Backgrounded Membrane Imaging (BMI) and Side Illumination Membrane Imaging (SIMI).

BMI's advanced capabilities allow for the detection of these low-refractive-index particles with unprecedented accuracy that is not achievable through conventional flow-based particle analyzers, further distinguishing them from product aggregates to ensure quality control during production.

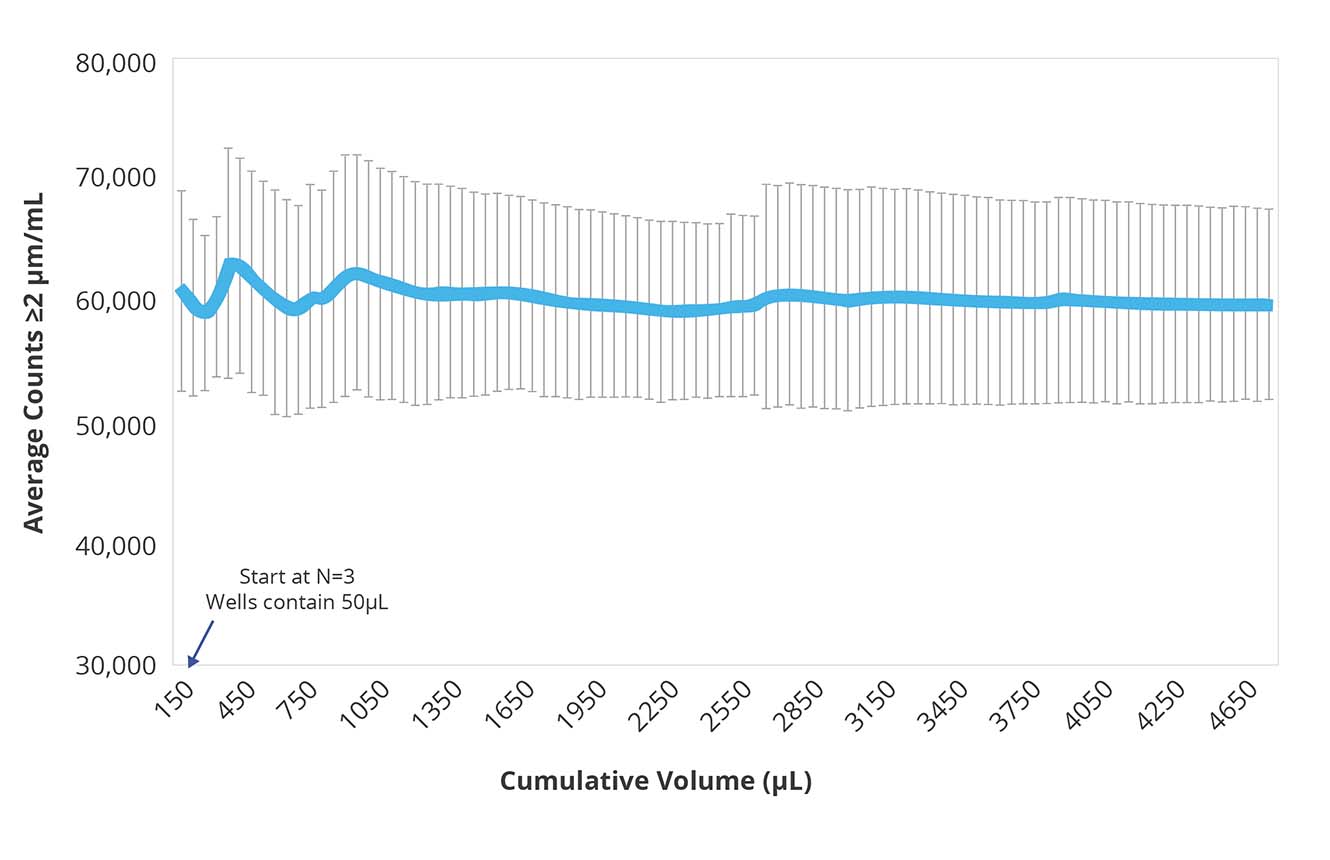

Get Consistent Counts No Matter the Sample Volume

Available samples are a moving target in lot release testing. Early on, the challenge lies in limited availability and the need for high-throughput methods to screen multiple candidates. As progress occurs and fewer contenders remain, larger product sampling can be achieved without sacrificing accuracy or quantitative results.

This continuous evolution calls for an adaptive system like Aura PTx, which can analyze 5 µL of samples to 10 mL when more is available.

Featured products

Frequently Asked Questions

Good Manufacturing Practice (GMP) release testing refers to analytical testing conducted on pharmaceutical products to ensure they meet predefined quality specifications before release for distribution or use. GMP release testing encompasses a range of quality control tests performed on drug substances, drug products, or finished dosage forms to assess their identity, purity, potency, and safety. These tests typically include physical, chemical, biological, and microbiological analyses, conducted according to approved testing procedures and regulatory requirements. GMP release testing verifies that pharmaceutical products comply with pharmacopeial standards, specifications established in regulatory filings, and internal quality control criteria, ensuring their safety, efficacy, and quality for patient use.

Release testing of pharmaceutical products involves a series of analytical tests to assess their quality, safety, and efficacy before they are released for distribution or use. The specific tests and procedures conducted depend on the type of product, dosage form, and regulatory requirements, but typically include:

- Identity testing: Verifying the identity of the active pharmaceutical ingredient (API) or drug product using techniques such as chromatography, spectroscopy, or mass spectrometry.

- Purity testing: Assessing the purity of the API or drug product by quantifying impurities, degradation products, or contaminants using chromatographic or spectroscopic methods.

- Potency testing: Determining the concentration or activity of the API in the drug product through bioassays, enzymatic assays, or chemical assays.

- Dissolution testing: Evaluating the rate and extent of drug dissolution from solid dosage forms using dissolution apparatuses and analytical techniques.

- Physical testing: Examining the physical properties of the drug product, such as appearance, uniformity of dosage units, hardness, friability, and disintegration time.

- Microbiological testing: Assessing microbial contamination levels in the drug product through sterility testing, microbial enumeration, or microbial identification assays.

- Stability testing: Conducting stability studies to assess the product's shelf life, storage conditions, and degradation profile under various environmental conditions.

Release testing is performed according to approved testing procedures, standard operating procedures (SOPs), and regulatory guidelines, ensuring the product meets predefined quality specifications and complies with regulatory requirements before it is released for distribution or use.

Testing for particulate matter involves identifying and quantifying particles present in pharmaceutical products or manufacturing processes to ensure product quality, safety, and compliance with regulatory standards. Common methods for particulate matter testing include:

- Visual inspection: Examining pharmaceutical products or manufacturing processes for the presence of visible particles (>50 micrometers) using magnification, lighting, or imaging systems.

- Light obscuration (LO): Using a light source and photodetector to measure the decrease in light intensity caused by particles passing through a small detection zone, allowing quantification of subvisible particles (2-50 micrometers) in liquid formulations.

- Microscopic analysis: Optical microscopy, electron microscopy, or scanning electron microscopy (SEM) visually inspect samples to identify and characterize particles based on their morphology, size, and composition.

- Dynamic image analysis: Capturing and analyzing images of particles in motion, allowing automated counting, sizing, and characterization of particles based on their shape, size, and optical properties.

- Filtration and gravimetric analysis: Methods that use membranes or filters to trap particles from air or liquid samples, followed by gravimetric analysis to quantify the mass of particulate matter collected on the filter.

These methods provide qualitative and quantitative data on particulate matter, enabling manufacturers to monitor and control particle levels within acceptable limits and ensure product quality and safety.

The United States Pharmacopeia (USP) provides testing specifications and standards for pharmaceutical products, excipients, and dosage forms to ensure their quality, safety, and efficacy. USP testing specifications encompass a wide range of parameters, including identity, strength, purity, performance, and quality attributes, established through collaborative processes involving experts from industry, academia, and regulatory agencies. These specifications are published in the USP-NF (United States Pharmacopeia-National Formulary) compendium, which is the official reference for pharmaceutical quality standards in the United States and many other countries. USP testing specifications provide guidance to manufacturers, regulators, and healthcare practitioners, facilitating the development, production, and evaluation of pharmaceutical products and ensuring their compliance with regulatory requirements and quality standards.

The United States Pharmacopeia (USP) provides testing specifications and standards for pharmaceutical products, excipients, and dosage forms to ensure their quality, safety, and efficacy. USP testing specifications encompass a wide range of parameters, including identity, strength, purity, performance, and quality attributes, established through collaborative processes involving experts from industry, academia, and regulatory agencies. These specifications are published in the USP-NF (United States Pharmacopeia-National Formulary) compendium, which is the official reference for pharmaceutical quality standards in the United States and many other countries. USP testing specifications provide guidance to manufacturers, regulators, and healthcare practitioners, facilitating the development, production, and evaluation of pharmaceutical products and ensuring their compliance with regulatory requirements and quality standards.

USP Chapter 788 provides guidelines and procedures for the inspection of injectable pharmaceutical products for particulate matter and discoloration. USP 788 establishes standards for particulate matter limits and acceptance criteria based on the route of administration, container closure system, and particle size. Particulate matter testing is critical for ensuring the safety and quality of injectable products, as particles can pose risks of embolism, thrombosis, or other adverse effects if administered to patients. Compliance with USP 788 is mandatory for pharmaceutical manufacturers to meet regulatory requirements and ensure product quality and patient safety.